The coarseness of a bandsaw blade is rated in teeth per inch (TPI), which refers to the number of teeth along a one-inch section of the blade. This measurement plays a crucial role in determining the cutting efficiency, smoothness of cuts, and overall performance of the blade.

Understanding the factors that influence blade coarseness and how to select the appropriate coarseness for different applications is essential for achieving optimal results when using a bandsaw. This guide will delve into the intricacies of bandsaw blade coarseness, providing valuable insights and practical advice for users of all skill levels.

The Relationship between Blade Coarseness and Cutting Performance

The coarseness of a bandsaw blade, measured in teeth per inch (TPI), significantly impacts its cutting efficiency and the smoothness of the cuts it produces. A blade with a higher TPI will have more teeth per inch, resulting in a finer cut with less material removed.

This type of blade is ideal for cutting thin or delicate materials that require a clean finish, such as wood veneers or metal sheets. Conversely, a blade with a lower TPI will have fewer teeth per inch, producing a coarser cut with more material removal.

This type of blade is better suited for cutting thicker or harder materials, such as thick lumber or metal pipes.

Factors Affecting Blade Coarseness

Several factors influence the coarseness of a bandsaw blade, including:

- Tooth Pitch:The tooth pitch, measured in TPI, is the number of teeth per inch on the blade. A higher TPI indicates a finer blade, while a lower TPI indicates a coarser blade.

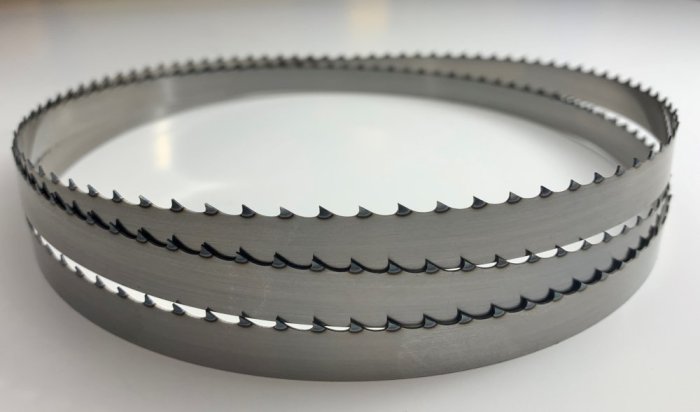

- Tooth Shape:The shape of the teeth also affects the coarseness of the blade. Hook teeth are designed for cutting hard materials, while skip teeth are designed for cutting soft materials.

- Material Composition:The material composition of the blade also influences its coarseness. Blades made from high-carbon steel or carbide are more durable and can handle tougher cutting jobs.

Choosing the Right Blade Coarseness for Different Applications

The appropriate blade coarseness depends on the material being cut and the desired cut quality. The following table provides recommended blade coarseness levels for different materials and applications:

| Material | Recommended Blade Coarseness (TPI) |

|---|---|

| Wood | 4-10 |

| Metal | 10-18 |

| Plastic | 6-12 |

Maintaining Blade Coarseness

Maintaining blade coarseness is essential for optimal performance and longevity. Sharpening and resetting blades can restore their original coarseness. Sharpening involves removing material from the teeth to restore their sharpness, while resetting involves bending the teeth back into their original position.

Troubleshooting Blade Coarseness Issues: The Coarseness Of A Bandsaw Blade Is Rated In

Common blade coarseness issues include excessive wear, uneven cuts, and blade chatter. Excessive wear can be caused by cutting too hard or abrasive materials. Uneven cuts can be caused by a dull blade or improper blade tension. Blade chatter can be caused by a blade that is too loose or too tight.

Helpful Answers

What is the relationship between blade coarseness and cutting performance?

Blade coarseness directly influences the cutting efficiency and smoothness of cuts. Blades with higher TPI (more teeth per inch) produce finer cuts with a smoother finish, while blades with lower TPI (fewer teeth per inch) make faster, rougher cuts.

What factors affect blade coarseness?

The coarseness of a bandsaw blade is primarily determined by the tooth pitch (distance between teeth), tooth shape, and material composition. Tooth pitch is measured in TPI, and tooth shape can vary from skip-tooth to raker-tooth designs.

How do I choose the right blade coarseness for my application?

Selecting the appropriate blade coarseness depends on the material being cut and the desired cut quality. For example, cutting thin, delicate materials requires a blade with higher TPI, while cutting thick, tough materials may require a blade with lower TPI.

How can I maintain blade coarseness?

Maintaining blade coarseness involves regular sharpening and resetting to restore the original tooth profile. Sharpening removes worn teeth, while resetting involves adjusting the tooth set (the alternating left and right bending of teeth) to ensure proper cutting action.

What are some common blade coarseness issues and how can I troubleshoot them?

Common blade coarseness issues include excessive wear, uneven cuts, and blade chatter. Excessive wear can be addressed through sharpening, while uneven cuts may indicate a need for resetting the tooth set. Blade chatter can often be resolved by adjusting the blade tension or reducing the feed rate.